Why is my diamond/carbon electrode broken?

Applies to

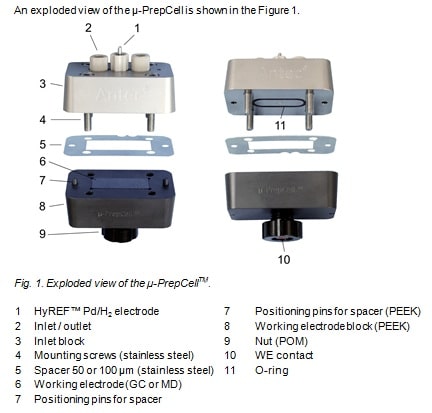

u-Prepcell

Summary

The large working electrodes of the micro Prepcell are fragile and might break under certain conditions (GC and BDD type). The electrodes are consumables, they are easily exchangeable and replaceable.

Cause

BDD and GC electrodes are likely to break for reasons of high solvent pressure over the cell, or a mechanical pressure point. Of course, accidental dropping the electrode might also lead to damage. Breakage by pressure over the cell is usually caused by:

- too high flow rate

- narrow bore capillary on outlet

- blockage of outlet, clogging

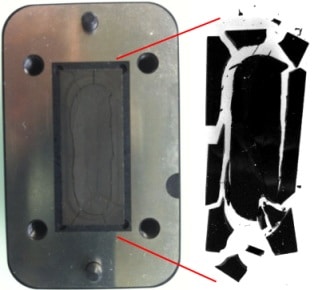

Breakage by a mechanical pressure point can be caused by:

- misplacement of electrode, not in but over the edge of recess

- obstruction under the electrode (object, or malfunctioning electrode contact)

- obstruction on top of the electrode (object stuck on the AUX)

- rubber ring is swollen (organic chemicals)

- wrong spacer thickness or no spacer at all

- closing the cell with extreme force (not using Antec’s hex key)

Remedy

To prevent breakage by pressure over the cell, follow the installation instructions in the Prepcell manual. When different connectors and tubing are used check the pressure drop by connecting the outlet tubing and other connecting parts to an HPLC pump (without the Prepcell) and set the flow rate. If the pressure is higher than the specified max pressure, adjust the tubing length/diameter accordingly. Check the cell for blockage of flow rate by flushing it with a syringe manually, remove any obstructions. To prevent mechanical pressure points, visually check for any object, and for damage to the WE block or connector, or the REF. Remove any unwanted objects and replace damaged parts. Check and replace the rubber ring (11) regularly. Loosen the nut (9) and WE contact (10) before assembly of the cell, and make sure the electrode stays in position in the recess in the WE block. Use at least 150 um spacer thickness (2 spacers) and do not apply force when closing the cell.