My peaks are (much) wider than to be expected

Applies to

HPLC, chromatography.

Summary

Peak width is much larger than expected.

Cause

Abnormal peak broadening, or loss of plate number can have several causes. By systematically eliminating all possible sources the problem can be found. Look back in your data when the problem first started, did it coincide with another change in your system (new mobile phase, changing a column etc)?

Causes related to chromatography:

- column with poor efficiency

- new mobile phase, incorrect concentration (ion pair, buffer, pH, modifier, additive)

- dead volume between injector, column, flow cell, poor connections, wide-bore tubing (especially critical in micro LC!)

- oversized sample loop: select a loop size close to or at the injection volume, for example: do not inject 5 µL using a 100 µL loop, but change for a 5 or 10 µL loop!

- excessive injection volume, see: max sample load

- sample buffer contains high concentration of modifier or ions, relative to mobile phase

- sample buffer pH differs from mobile phase pH

- detector setting: too strong filter setting results in broader peaks

- flow cell related things below.

Flow cell related:

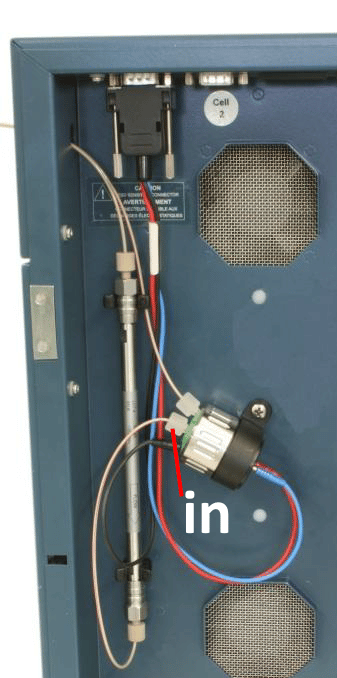

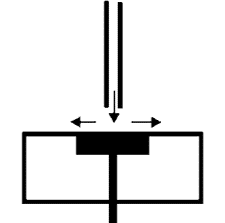

- Inlet and outlet are reversely connected. Tubing IN should be in the center hole, pointing at the WE in the middle of a VT or SenCell.

- Typical for wall jet flow cells only: fingertight fitting at the flow cell inlet is not properly connected. The tubing should protrude about 1.5 cm (0.6″). If less, a large dead volume exists. When connecting the tubing, have enough tube protruding when putting the fingertight in the thread of the cell inlet. This applies to the VT03 and SenCell, not the FlexCell.

![]()

Fig. 1. The inlet tubing is connected in the middle/centre of the the cell. The liquid goes out sideways, in case of a wall jet cell. The tubing should protrude a bit to avoid dead volume. Only the Flexcell is different, no difference between in and out port, and tubing is only a few mm protruding from the fingertight.

Remedy

Optimize chromatographic system. Connect the HPLC tubing properly as described in the manual. Avoid dead volumes, such as connections or tubing that may have too much volume (too large diameter or too long). For cleaning, maintenance and installation of flow cells see flow cell manual. Turn off data filter setting to see if it makes a difference. Check the peak width with a standard in mobile phase, or a low concentration solvent without any modifier. If such standard gives nice sharp peaks, it indicates that the problematic samples have an incompatible solvent, pH or substances.