High background current

Applies to

Electrochemical detector

Summary

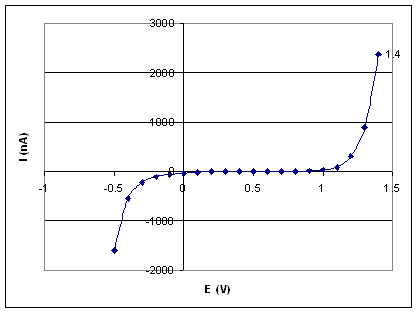

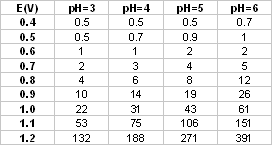

The background current is related to the working potential, working electrode (WE) diameter, WE material and the mobile phase. Therefore, to recognize an abnormally high background current, its normal value should be considered. If an increase from 5 to 15 nA is seen, it is not normal. However, an increase from 120 to 130 nA is acceptable. The best reference is your own experience. However, if you are not sure what is acceptable the I/E plot in this document may be of help. To find out whether the cell current is normal or not consider your cell potential, electrode diameter and pH.

Fig. 1. Typical cell current (in nA) for 2 mm glassy carbon flow cell with an Ag/AgCl reference electrode, and a 50 mmol/L phosphate/citrate buffer.

Table I. Typical cell current (in nA) for 2 mm glassy carbon flow cell with an Ag/AgCl reference electrode, and a 50 mmol/L phosphate/citrate buffer.

Please realize that given values are only an estimation of what roughly would be a ‘normal’ cell current. Only if your cell current is more than a factor of 2-3 away it may indicate a problem.

Cause

An abnormal increase in background current is caused by:

- Contaminated mobile phase

- Retained peaks from previous runs

- Column is ‘bleeding’

- High amount of Fe++ in buffer

- In reductive amperometric detection: poor degassing of mobile phase, see topic.

- Malfunctioning reference electrode

- Salt bridge in REF not saturated

- Corrosion of cell cable

- Chemical treatment or damage to working electrode

- Malfunction in electronics (voltage clamp)

- Incorrect detector settings, method not optimized

Diagnosis

In case of an abnormal increase in background current a 3-step procedure helps to locate the source:

- dummy cell test

- failed: malfunctioning electronics or wiring to PC

- passed: not related to electronics

- continue with stop flow test

- stop flow test

- failed: LC related problem (mobile phase, tubing, pump, pulse damper, autosampler, column, bubbles, contamination)

- passed: not related to electronics or HPLC system

- continue with leakage flow cell test

- flow cell contact test

- failed: service, or replace flow cell

- passed: not related to electronics, HPLC system, or leakage flow cell

- call for support to find other source

If the cell current is extremely high or even in ‘overload’ the working electrode may be damaged or leaking. If the working electrode is recently polished or treated with chromic acid, or if a high cell potential has been applied for a while, it will take some time before it stabilizes to a normal cell current. If the background current is in-scale, and suddenly runs off-scale completely, the problem may be chromatographic (something comes of the column).

Remedy

In case of contamination of the mobile phase, a few steps can be made to localize the cause of problems.

- Take out the HPLC column and switch on the pump. If the background current is normal, then the column is the cause and should be cleaned or replaced.

- If not, prepare a fresh mobile phase, and do not recycle the mobile phase. Add 0.1 mmol/L EDTA to buffer. This treatment helps if metal parts are contaminating the mobile phase with Fe2+ ions. At high cell potential EDTA may be less effective because it is oxidized itself. In that case rinse metal parts with 15% HNO3 to passivate.

- Servicing the reference electrode will help with problems related to this electrode. Typically, the chloride salt in a salt bridge must be refreshed and saturated with chloride salt crystals.

- Check cell cables for electrical contact.

- If the working electrode is treated or damaged, it can be seen. The electrode surface lacks its mirror like surface.