OQ or PQ is ‘failed’

Applies to

ALEXYS system, electrochemical detector

Summary

OQ or PQ is ‘failed’.

Cause

Several possible causes for ‘failed’ result:

- electronic malfunction

- problem with chromatography, equipment, flow cell, cable connections or data acquisition

- problem with a test tool, column or standard sample.

- incorrect setting or erroneous calculation

Diagnosis and Remedy

If out of spec the detector needs service or maintenance. Contact your supplier. To exclude artificial observations always use calibrated test tools and freshly prepared sample solutions. Signal test: If out of spec check for the expiration date of standards and verify that the samples have been stored under recommended conditions. Although every new flow cell is QC tested before shipment and handled with care, we recommend to open an inspect the cell. See manual for cleaning instructions. Cleaning with a tissue with methanol may be necessary. In case of doubt, it or if the peak height for the standard sample is too small it is recommended to do another test with a new freshly prepared sample. Noise test: if out of spec check the cell current in display. Typically, 2 or 3 decimal digits are visible when working in the pA range. Look at the display for 10 seconds and write down the max and min cell current. For example, if display values are between 2.611 and 2.613 nA it means that the measured peak to peak noise must be about 2 pA. In other words, it is a double check that all calculations are done correctly

.

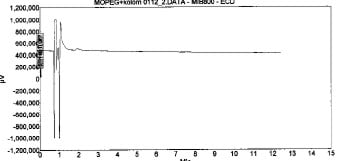

Fig. 1. OQ signal failed upon installation (no MOPEG visible at t = 4 min).

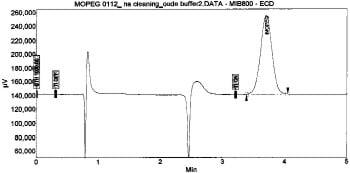

Fig. 2. OQ signal passed after cleaning flow cell with tissue with methanol.