Welcome to our Knowledge Base

AS 100 error: spindle does not rotate

Summary

When a problem occurs in the AS 100 an error code or explanation is visible in the system status window.

Cause

The sample needle or syringe spindle does not rotate correctly. The software tells the syringe or sample needle to move up or down but there are no pulses generated by the sensor. This error can have several causes. Some of them are related to obstruction of the syringe or needle movement, other are related to electronic problems.

Diagnosis and Remedy

- Sample needle: check the sample needle mechanism for any obstructions.

- Sample needle is broken

- Tubing of sample needle sticks behind sample loop

- Prepuncturing needle is bent (replace!)

- Rest (sample) material in between prepuncturing needle and sample needle (the sample needle sticks in the prepuncturing needle)

- Transport block sticks on shaft (clean shaft)

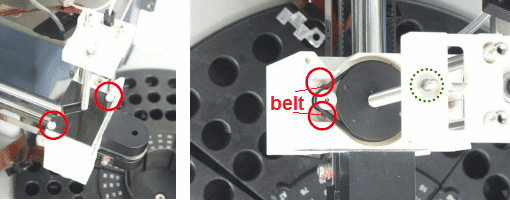

- Belt broken (belt of the small DC motor which drives the needle spindle), see picture:

Fig. 1. Belt that drives the injection needle.

If the above mentioned reasons are not the cause, it is an electronics problem such as:

- Sensor defect

- DC Motor brushes worn-out

- Flex PCB broken or interrupted

See user manual for error descriptions. Please consult the service manual or supplier.